New swimwear and lingerie collection from Italian knitter

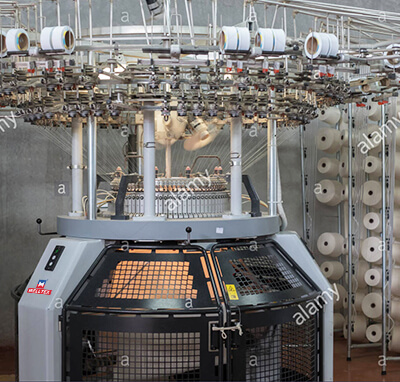

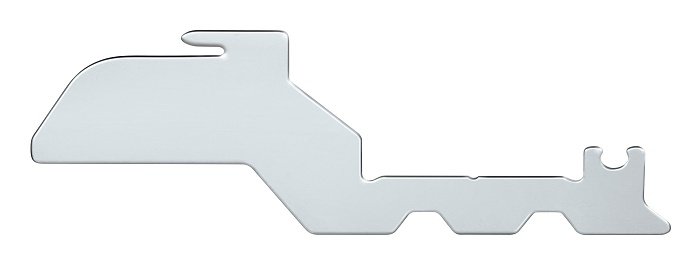

Brugnoli Giovanni S.p.A., introduces new swimwear and lingerie collection - Extrasize extrajacquard. © Brugnoli Giovanni S.p.A. Intimate Apparel, Swimwear/Beachwear Leading Italian circular knitted fabrics manufacturer Brugnoli Giovanni S.p.A., is further developing its well-known ExtraJacquard technology dedicated to swimwear fabrics. ExtraJacquard is a Brugnoli technology engineered to create extra flat the fabric. It is said to be the best solution for unparalleled colour definition, flexibility in creativity, creating logos or any other design, as well as also being visible on the back of the fabric. During this season Brugnoli says it is going even further with the creation of ‘extralarge’ design. Flat fabrics with embossed details New developments of flat fabrics with embossed details to create movements and convey a happy mood. Alphabet, small patterns - are created either with contrasting colours or tone on tone, according to the required result. Ideal for swimwear and sportswear. Transparencies with lace effect for lingerie and out-of-water Easy-going lace effect, to be used in easy-care and young lingerie but also to add feminine details on sporty garments. Transparencies with MyNy technology by Brugnoli, deliver comfort and freedom of movement, breathability and wrinkle-free fabrics. Double face explosive technology Fabrics with Explosive technology by Brugnoli, are perfectly shaping, with high muscle sustain end with extreme comfort. Perfect for sportswear, ideal for swimwear, comfortable for ready to wear. Until now, Explosive technology fabrics were mainly in solid colours, but today it is possible to add movement effects and double face colours, created with eco-sustainable recycled polyamide. Several colour combinations are presented for swimwear, sportswear and ready to wear. © Brugnoli Giovanni S.p.A. Since 1952 Brugnoli has created circular knit fabrics 100% made in Italy for ready to wear, sports, swimwear and lingerie with innovative and eco- sustainable tailor-made solutions for perfect fit garments of brands in more than 70 countries. Brugnoli has a wide collection of fabrics in polyamide, also recycled, bio-based (Br4 technology-patented) or with enhanced biodegradability - extra fine merino wools with a technical flawless approach both for ready to wear and active lifestyle, protective fabrics for outdoor with stretch membrane, waterproof, windproof and breathable. Together with a specific offer of fabrics for comfortable shirts, trousers, lights and transparencies. Throughout the years Brugnoli has developed several proprietary textile technologies, some of which also have been granted patents. The company says it has been committed to ‘eco-sustainability’ for several years and has been granted certifications such as GRS - Global Recycled Standard, RWS - Responsible Wool Standard, ZDHC - Roadmap to Zero, Oekotex Standard 100, Tessile e Salute, BCI - Better Cotton Initiative, Supima Cotton. www.br...

View More