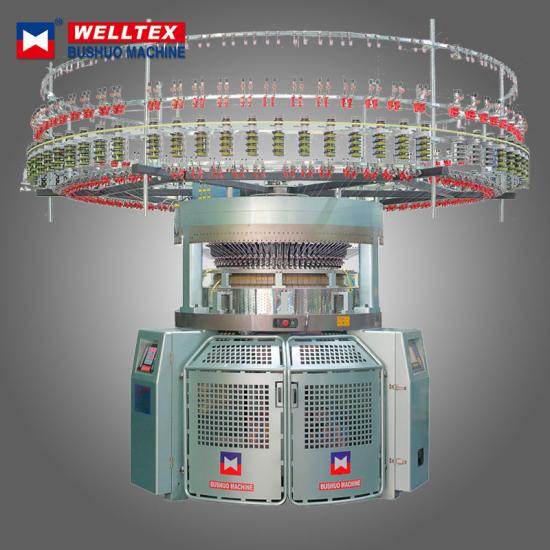

Machine Description:

The interlock or rib knit machine possesses two tracks cams for the dial and fours tracks cams for the cylinder. You can easily and rapidly change the arrangement of cams and needles to knit twill, air layer fabric, interlining fabric, bourrelet, pique fabric, double sided elastic cloth, small jacquard fabric and so on. The multifunctional product supports the replacement of cams and needle cylinders with different numbers of needles, so as to serve as an interlock knitting machine or a rib machine, and successfully adapt to market change. Moreover, due to the 2 tracks plus 4 tracks mechanism, it is even able to produce more complex fabric like the lower texture of high grade clothing.

1. The main gear transmission of dial and cylinder in the WD series double jersey machine are the oil bathed lubrication. This design can deduce the running noise, energy loss, and part worn out, also provide higher operating RPM in production.

2. Considered the various yarn material applications, the knitting head of WELLTEX interlock machine can offer the best solution for different request in knitting, like fine polished and hardness cam, the feeding angle of the yarn guider.

3. Depending on the pattern structure in the world different market, WELLTEX has several yarn guider model and cams model, including WD/2.1F, WD/2.5F, WD/2.8F, and WD//4.1F etc. With optional pattern cams supply, the fabric structure can be easy to reach the pique or complex pattern request. As per your demand we choose the best cam design model for you. The interlock machine can be from 18 gauge to fine gauge 44 gauge.

4. In 2+2 cam track type, fabrics not only plain interlock fabrics, also punte de roma, eight lock double pique, single pique, wet ripple, and reversible etc.

5. The 2+4 track cam arrangement system which can produce pattern like twills, herringbone, creapes, double lacostte, vertical striper, and small pique etc.

Workable yarns:

silk, cotton,blend, polyester viscose and synthetic fibers, etc.